Hunan Yiyang Project: The 600㎡ Space Transforming Into A Profit-Maker

文章目录[隐藏]

4-meter ceiling height, compact space, limited budget — these were the triple constraints presented by the client. Yet it was on this seemingly “impossible” blueprint that the Midong team, armed with data and simulations, unlocked a business miracle: 600,000 yuan in revenue over the 6-day National Day holiday.

This transformation was never about simply “drawing a few renderings and placing some equipment”. We had to answer three critical questions: What can fit into 600㎡? What attractions work with a 4-meter ceiling? How to recoup investment within 18 months?

Step 1 | Project Objectives

Define “excellence” with hard data

When we took over the Yiyang project, we faced a complex challenge: 600㎡ small space, 4-meter height restriction, and a wide customer base of 3 – 12 years old — each constraint squeezed the design flexibility.

We first set three sets of non-negotiable metrics for the project:

Business Goals

-

Per customer price: anchored at 80 – 120 yuan -

Target daily foot traffic: 800 visitors -

Occupancy rate: maintained above 60% -

Investment payback period: controlled within 3 months

Space Boundaries

-

Measured ceiling height: 4 meters -

Load-bearing capacity: compliant with GB50009 standard -

Electrical load: sufficient for large equipment operation -

Providing safe and efficient physical support for functional layout of every inch of space

Equipment Ratio

-

Signature attractions (Light Wheel Moto, 360-Degree Bicycle): 40% (responsible for customer acquisition and photo-sharing) -

Repeat-visit drivers (Trampolines, Obstacle Courses): 60% (enhancing customer stickiness) This ratio directly determines post-opening repeat visit rates.

Step 2 | Initial Design

Minimize trial-and-error costs on paper

In the initial phase, we delivered 3 sets of plans for client selection, all adhering to the same core traffic flow logic:

Four-Functional-Zone Quadrant

-

Entrance Attraction Zone (360-Degree Bicycle + Light Wheel Moto Display)

-

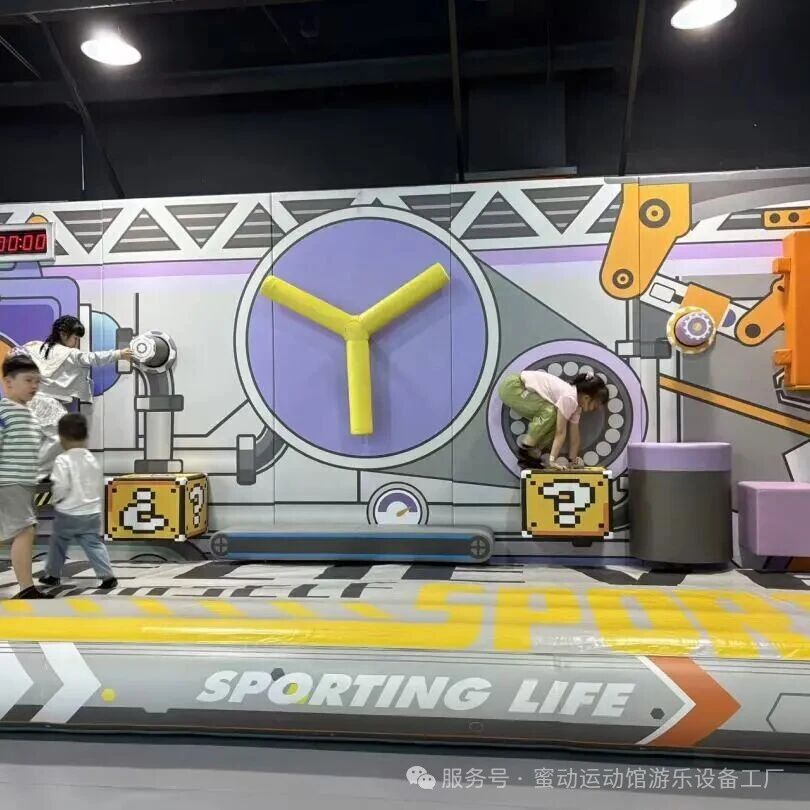

Parent-Child Interaction Zone (Trampolines + Mario-themed Obstacle Course)

-

Extreme Challenge Zone (Rock Climbing + Physical Fitness Obstacles)

-

Rest & Viewing Zone (Parents can monitor 80% of the play area)

Three-Dimensional Traffic Flow Design

From Customers’ Perspective

-

The 360-Degree Bicycle at the entrance attracts photo-taking -

Light Wheel Moto positioned at the center creates a visual focal point -

Trampolines and obstacle courses on both sides form a “loop” traffic flow to avoid congestion

From Parents’ Perspective

-

Rest area is located on a high platform at the edge of the venue -

Overlooking the entire site with unobstructed views -

Safety radius covers the toddler play area

From Operational Perspective

-

Service desk, storage area, and arcade zone form a secondary consumption path -

Estimated conversion rate: 25%

Thematic Color Scheme

Industrial Gray + Contrasting Orange & Blue Aesthetics

-

Gray: lowers visual center of gravity to alleviate ceiling oppression -

Orange: strengthens energetic brand memory -

Blue: echoes the tech-themed concept This color palette later became the venue’s most distinctive identity.

Step 3 | Plan Validation

Turn “aesthetic appeal” into “feasible execution”

This was the make-or-break phase of the project. We conducted three rounds of validation on the initial design:

Compliance Verification — Safety is Non-Negotiable

Aligned with GB8408 and EN1176 standards, we conducted rigorous inspections:

-

Trampoline Zone: 1.2m drop height, equipped with 30cm-thick EPE cushioning mats -

Rock Climbing Bouldering Zone: 200mm protective mats at landing points, meeting drop test requirements -

Physical Fitness Obstacles: Guardrail spacing controlled within 85mm to prevent children’s head entrapment -

All Soft Padding: Passed B1-level flame retardancy test, with joint chamfers of R≥5mm

These data weren’t just for show — they gave the client full confidence in safety and compliance.

Operational Validation — Traffic Flow Drives Revenue

We simulated peak weekend foot traffic:

-

Average 3-minute stay at the entrance 360-Degree Bicycle, accommodating 20 families per hour for photos -

Average 25-minute playtime on trampolines and obstacle courses, with 2.4 turns per hour -

Rest area seating ratio: 0.6 seats per visitor to avoid parent overcrowding -

Comprehensive analysis: dynamically accommodating 100 families during peak hours

Key Insight: Relocating the Disco Turntable from the center to the end of the traffic flow increased overall circulation efficiency by 18%. This adjustment was completed during the blueprint phase, eliminating on-site rework costs and delays.

Financial Validation — Invest with Clear ROI

We provided the client with a 3-scenario ROI calculation table:

-

Conservative Scenario (Off-Season Benchmark): 300 daily visitors, 6-month payback period -

Baseline Scenario (Peak-Season Average): 600 daily visitors, 3-month payback period -

Optimistic Scenario (Holiday Peak): 800 daily visitors, 2-month payback period

The actual National Day data validated our projections: 600,000 yuan in 6-day revenue — 20% exceeding the baseline.

This table clarified the value of the 50,000-yuan investment in the Light Wheel Moto: Absolutely worthwhile. Its photo-sharing effect boosted organic foot traffic by 15%.

Step 4 | Mass Production Launch

Implement a “Change Control Gate” to Prevent Rework

After plan approval, we signed a Design Freeze Confirmation with the client, clarifying three key points:

Frozen Design List

-

Thematic color scheme (Gray + Orange + Blue) -

Final traffic flow layout -

Equipment BOM list (including specifications and models) -

Material grades (45# steel, B1-level flame-retardant soft padding) -

Delivery timeline (production and on-site arrival within 60 days)

Change Management Mechanism

Post-freeze adjustments require a formal change order process. For example, if the client requested increasing the rock climbing wall height from 2.8m to 3.2m, we clearly communicated: +12,000 yuan in additional cost, +7-day delay, implementation upon written confirmation.

Production Tracking

Every production step — from steel warehousing to equipment shipment — was documented with photos. Clients could track progress via a real-time dashboard:

-

Steel fabrication completion rate -

Soft padding production schedule -

Final assembly and testing milestones -

Logistics and delivery timeline Full transparency throughout the entire process.

Conclusion

Mitigate Risks in Advance, Achieve Profitability on Opening Day

The success of the Yiyang project was no accident. While competitors relied on intuition, we used data, checklists, and validation processes to eliminate risks during the blueprint phase.

Every decision — from placing the Light Wheel Moto at the center, to allocating 25% of the color ratio to orange, to designing the loop traffic flow — passed the triple validation of compliance, operations, and finance.

This methodology is Midong Amusement’s first “insurance policy” for every client.

Book a project consultation today. We’ll apply this rigorous validation process to your venue, ensuring every investment decision is data-driven.